Polybutylenterephthalat

With our partners DSM Engineering Plastics, Chang Chung Plastics and TEREZ PERFORMANCE POLYMERS we offer our customers a broad portfolio.

Arnite® (PBT, PET and blends) are high-performance engineering plastics that combine high strength and rigidity with excellent processing characteristics.

As a result, Arnite A (PET) and Arnite T (PBT) are well suited for a broad range of automotive, electrical & electronic and consumer goods applications. A wide portfolio of Arnite is available including unreinforced, reinforced and flame retardant grades.

From Automotive to E&E

DSMs innovative high performance are developed to meet a wide variety of technological challenges. Industry experts, scientists and engineers work hand in hand with us from TER Plastics and our customers to develop next generation solutions.

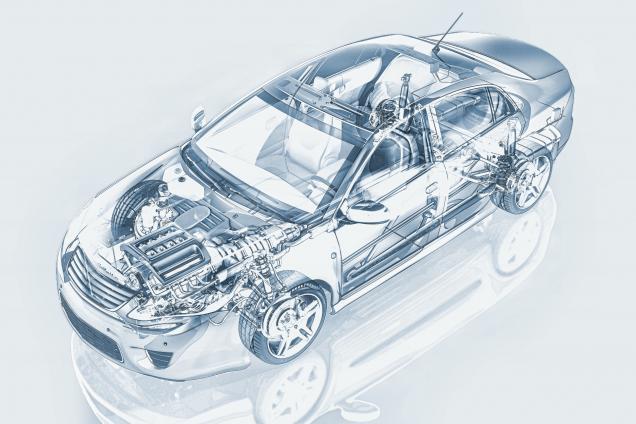

Arnite is ideal for a wide range of demanding automotive applications – from the braking system to adaptive forward lighting, to windscreen wiper housings etc.

The good match of product characteristics and processability of Arnite and the demanded

properties in the Electrical and electronic industry makes Arnite the material of choice.

Polyesters Processing molding conditions:

PBT:

T (Melt) = 250-270°C

T (Mold) = 60-100°C

PET:

T (Melt) = 270-290°C

T (Mold) = 130°C at least

Longer cycle times (slower crystallization compared to PBT)

Polyesters and polyamides are used in very similar applications.

Similarities:

- High strength and stiffness (especially when glass fibers are added)

- Excellent processing characteristics during molding and extrusion (similar cycle times, PET somewhat longer)

- Very resistant against various chemicals

- Can both be used up to quite high temperatures (HDT above 200°C)

Differences:

Polyamides:

- In general higher ductility (toughness) depending on the conditions (hinges, snap-fits)

Polyesters:

- Better dimensional stability (low water uptake)

- Properties (a.o. electrical) not moisture dependent

- Better color stability for lighting applications