TPE-V

With

our partner Teknor Apex, we can offer excellent possibilities in the area of

TPV.

TPV materials are a compound like many

plastics. The basis of TPEs are a thermoplastic and an elastomer component. The

thermoplastic phase functions as a hard segment, while the elastomer assumes

the function of the soft segment. Unlike alternative thermoplastic elastomers

(such as TPE-U or TPE-E), the hard and soft segment is not chemically coupled,

but is physically blended. The basis for the former is the polypropylene (PP),

while ethylene propylene diene-monomer rubber (EPDM) is the basis for the soft

segment.

Using TPV offers the following product benefits:

- Flexibility, also in the low-temperature range

- Excellent UV stability

- Listed by many OEM’s such as Ford,

VW, Audi, etc.

- Very good acid and alkali resistance

TPV is often used in the automotive industry for

the following applications:

- Claddings

- Air ducts

- Footwell mats

- Rubber gaiters

- Seals

- etc.

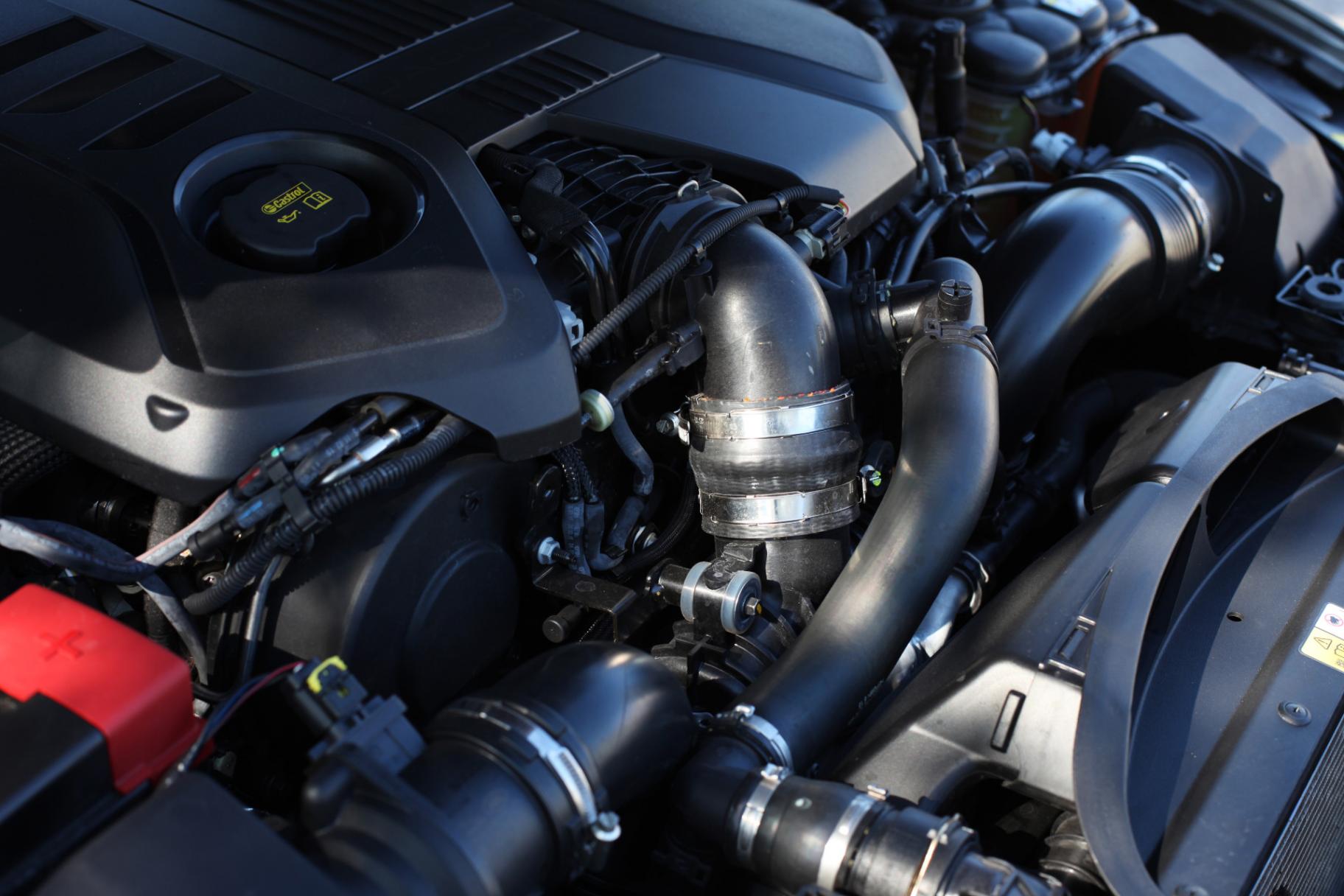

Vehicle air ducts

Vehicle air duct systems transport clean and air-conditioned air to the desired location within the vehicle. The functionality of the seals is decisive in this particular case.

Using TPV for vehicle applications offers the following product benefits:

- Cost savings

- Weight reductions

- Improved

longevity

- Improved

sealing function

- Excellent

processability

- Temperature

stability up to 125°C

- Resistant

to cleaning agents and oil