PA6T/6I & PA6T/66

The subject of metal replacement already engages the plastics industry for many years; this is because the use of plastic instead of metal implies economic and ecological benefits. Plastics offer weight reduction, freedom of design, sustainability, and finally high stiffness and strength values. Also, operation temperatures up to 230 °C can be achieved.

The TER Plastics POLYMER GROUP has a comprehensive product portfolio around the topic of metal replacement. This includes technical and high-performance polymers from Envalior and TEREZ PERFORMANCE POLYMERS. The new product series TEREZ® HT100/HT200/HTE were designed for high mechanical requirements in combination with high operating temperatures.

TEREZ® HT 100 for High Temperature Application

The product

line TEREZ® HT has a melting point of 330 °C and thus the best conditions for

high temperature applications. Excellent creep resistance is already given

starting at an ambient temperature of 100 °C.

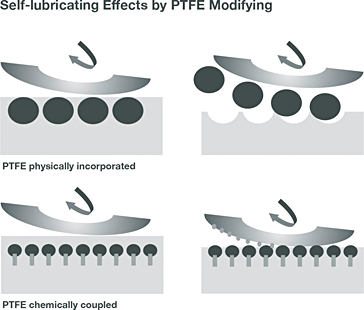

Tribological Modifications

In

combination with PTFE excellent tribological properties with the product lines

TEREZ® HT100/HT200/HTE can be achieved. The coefficient of friction and wear is

significantly reduced. For this, the PTFE is chemically coupled with the PPA,

resulting in constant sliding properties and an extended life cycle.

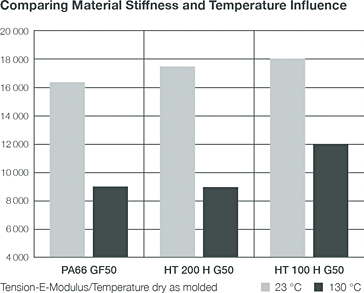

The determined level of stiffness at 23 °C and 130 °C shows the superiority of the TEREZ® HT series at high temperatures.

The reasons that speak for our products are as varied as their uses:

- Lower

material costs

- No / less rework required

- Resistance to corrosion

- Excellent abrasion and sliding properties

- Weight reduction

- Sustainability

- Freedom of design

- High stiffness and strength values